Demonstrations Page 6 - Thermodynamics

and Phase Changes

Scroll down to view photographs and short descriptions of

some of the demonstrations in the list below.

WARNING – Use at your own risk! We cannot guarantee the accuracy or the safety of these activities. Some of these activities are far more dangerous than others. The contributors and Bradley University do not assume any responsibility for these activities or their results. If you have questions, corrections, or comments please do not hesitate to contact Dean Campbell (campbell@bumail.bradley.edu) at Bradley University.

- Ferrofluid

Demonstrations

- Refrigerator

Magnet Demonstrations

- Polydimethysiloxane

Demonstrations

- LEGO® Brick Chemistry and Nanotechnology Demonstrations

- Spontaneous Assembly (or "Self

Assembly") of Hot Dog Slices

- Cut hot dogs into ~1 cm thick slices and place them in a

pan of water. They will float at the water's surface and attractive

capillary interactions will draw them together into an organized

close-packed array.

- References:

- Dungey, K. E. J. Chem. Educ. 2000, 77,

618.

- Campbell, D. J.; Freidinger, E. R.; Hastings, J. M.; Querns,

M. K. "Spontaneous Assembly of Soda Straws." J.

Chem. Educ., 2002, 79, 201.

- Campbell, D. J.; Freidinger, E. R.; Querns, M. K. "Spontaneous

Assembly of Magnetic LEGO® Bricks." The Chemical

Educator, 2001, 6, 321.

- Campbell, D. J.; Freidinger, E. R.; Hastings, J. M.; Querns,

M. K. "Spontaneous Assembly of LEGO®s." Chem13

News, Sept., 2001, 8.

-

- ABOVE LEFT: Cutting hot dogs into slices. ABOVE RIGHT: Floating

them in a pan of water. Note: sometimes tapping the pan will

help shake out some of the defects in the assembled pattern.

-

- Thermochromic Battery Tester

(thermochromic leucodye film)

- The built-in battery testers on common alkaline batteries

are based on films of thermochromic inks called leucodyes. When

the test "buttons" on the battery are pushed, a current

from the battery flows past the leucodye film, heating it slightly

and causing it to lose its color. To check this, I cut the battery

tester off an Energizer® "D" cell with a razor

blade. At room temperature the film appears dark, but body heat

can change the leucodye layer to colorless, exposing a green

background layer that provides contrast so the black-lettered

word "GOOD" may be read. The Energizer® and Duracell®

battery testers checked by Robert Bailey changed color at roughly

40 C.

-

- References:

- White, M. A.; LeBlanc, M. "Thermochromism in Commercial

Products" J. Chem. Educ., 1999, 76,

1201.

- Viiri, J.; Kettunen, L. "Temperature Profile of the

Duracell® Test Strip" Phys. Teach., 1996,

34, 276.

- Clark, R. W.; Bomicamp, J. M. "Tapered Resistors"

Phys. Teach., 1995, 33, 340.

-

- BELOW LEFT: The battery tester at room temperature.

- BELOW RIGHT: The battery tester in contact with a metal cup

of hot water as a source of heat.

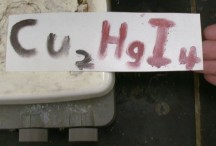

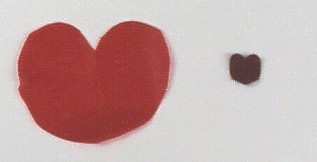

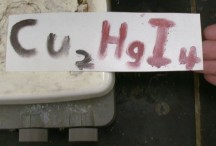

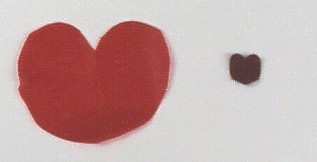

- Copper Mercury Iodide

(thermochromic powder)

- The synthesis and properties of this inorganic solid is described

in Ellis et al. "Teaching General Chemisty: A Materials

Science Companion." The material undergoes a phase transition

from a red solid at room temperature to a dark brown solid above

~55 C. This is due to enhanced ion mobility in the high-temperature

phase. When the synthesis is complete, the dry powder may be

smeared onto heavy paper and then laminated with transparent

tape or contact paper. This provides a means of handling the

material without coming into direct contact with the mercury

compound. The entire demonstration card may be heated with a

heat gun or a hot plate to illustrate the phase change.

- ABOVE LEFT: A Solid State Model of the low-temperature phase

of copper mercury iodide.

- ABOVE RIGHT: Smearing copper mercury iodide on heavy paper.

Note the use of gloves and goggles.

- BELOW LEFT: The demonstration card at room temperature.

- BELOW RIGHT: The left side of the demostration card on a

hot plate. Note the darkening of the powder.

- Special thanks to Dr. David Shaw at the Madison Area Technical

College for providing the pictures.

-

- Memory metal (solid-solid

phase change)

>>>

bend >>>

>>>

bend >>> >>> apply heat >>>

>>> apply heat >>>

-

- ABOVE: Nitinol or "memory metal" as it is called

is a nickel-titanium alloy that may be "trained" to

remember its shape. If the proper kind of memory metal is trained

to a particular shape in its low temperature or martensite phase

(left) and is then bent out of shape (middle), then gently heating

the metal with a heat gun or hot water to its high temperature

or austenite phase will restore the metal to its trained shape

(right). Training the metal involves heating it to a much higher

temperature, such as that of a candle flame.

-

- To train a piece of wire, bend it to the desired angle outside

of a candle flame. Then hold onto the wire tightly and

place the desired bend point into the candle flame. Since the

material is a metal it will conduct heat, so you may find that

holding the wire with gloves or pliers is desireable. The wire

will initially try to straighten out as it heats up, but if you

hold the wire tightly it will then soften at the point

of the wire in the flame, creating a nice, tight bend. The hot,

bent wire may be cooled in water. The Institute for Chemical

Education sells memory metal versions of its ICE logo.

-

- Homemade Shrinky Dinks®

- Transparent polystyrene packaging such as those used to hold

baked goods can be used to make plastic trinkets. (Not all clear

packaging works. Polystyrene containers should have a number

6 inside the recycling triangle on the plastic.) When the plastic

is heated, stretched-out polymer chains have enough energy to

relax their orientations. As a result, thin flexible sheets of

the clear polystyrene will shrink laterally, thicken, and become

less flexible. Writing that was placed on the surface of the

polystyrene with permanent markers will also shrink. This polymer

behavior is the basis for Shrinky Dinks®, a craft/toy that

was popular in the 1970s and 1980s, and can still be purchased

today.

-

- ®Shrinky Dinks is the Registered Trademark of K &

B Innovations, Inc.

-

- ABOVE: The polystyrene "windows" on envelopes can

be used to make Shrinky Dinks®. Before (LEFT) and

after (RIGHT).

- BELOW: Patterned polystyrene sheets before (LEFT)

and after (RIGHT) being placed in an oven. Use a relatively

low temperature (about 65 C) or they will melt rather than shrink!

NOTE: Many but not all sheets of polystyrene will shrink and

not all sheets will shrink equally in all lateral directions.

- BELOW LEFT: Making clear polystyrene icicles. There is

a significant burn risk here. A polystyrene sheet placed

on aluminum foil in a toaster oven at 300 F or simply to "toast"

mode will shrink fairly quickly (it is fun to watch - but don't

leave them in the oven too long or they might melt). A narrow

triangle of polystyrene container material, with a hole punched

in the top, is shown at LEFT. The wrinkles usually flatten out

upon heating. While the shrunken sheets are still hot,

remove them from the oven, twist them quickly into a spiral shape,

and hold until they have cooled, as shown at RIGHT. If the shape

of the twist is unsatisfactory, placing the icicle back into

the oven will untwist it. Again, there is a significant burn

risk here. My wife loaned me her thimble to provide a measure

of protection.

- BELOW RIGHT: One can make interesting faces on polystyrene

sheets, shrink them, and attach them to pom-poms. (Hot melt glue

works much better than school glue for this.) Placing a magnet

on the back enables the decoration to stick to a refrigerator

door. The picture below includes a couple versions of moles (a

popular mascot for chemists) and a tomato cartoon character that

is popular in the Campbell household.

-

-

-

-

- Liquid Nitrogen Demonstrations

- Kylee Korte, Phuong Nguyen, and Joel Kouakou assisted in

preparing these descriptions.

-

- CAUTION: Liquid nitrogen is very cold and presents a serious

frostbite hazard, especially if it gets trapped against your

skin (e.g.in your clothing). Additionally, gaseous nitrogen occupies

more volume than the same quantity of liquid nitrogen. Gaseous

nitrogen produced quickly enough in sufficient quantities can

displace oxygen from the air. Containers filled with liquid nitrogen

could fail without warning due to thermal shock or gas pressure.

Protect yourself accordingly.

-

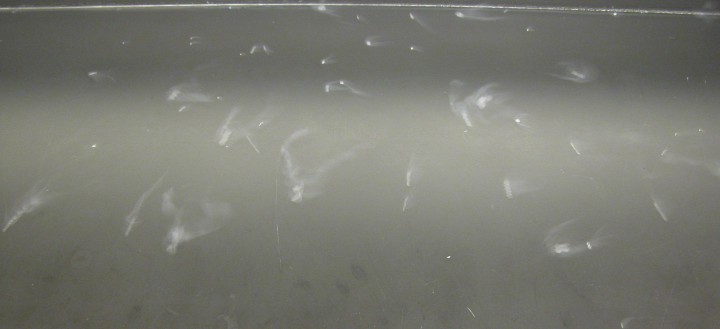

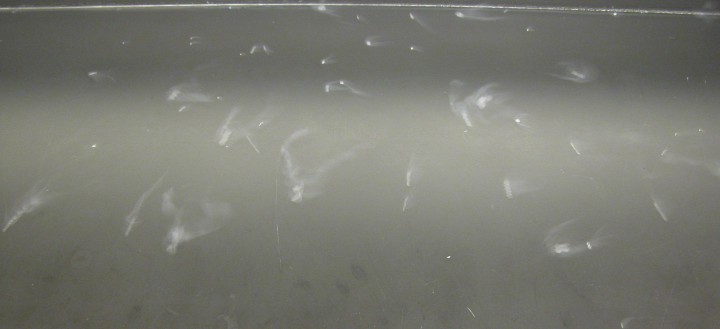

- Leidenfrost Effect

- Named after Johann Gottlob Leidenfrost, a German doctor,

the Leidenfrost Effect is an occurrence where a liquid comes

in contact with a material that is much hotter than its boiling

point and creates a vapor layer to prevent it from further direct

contact with the material. The liquid then boils much more slowly

as it is protected by the insulating vapor layer. Liquid nitrogen

on a smooth surface at room temperature can illustrate this phenomenon.

The liquid nitrogen is obviously the liquid and the surface

is the material that is much hotter than it. Droplets of the

liquid nitrogen will move easily across the surface, supported

on cushions of nitrogen vapor.

- Reference:

- Wikipedia: Leidenfrost effect. http://en.wikipedia.org/wiki/Leidenfrost_effect

(accessed June, 2006).

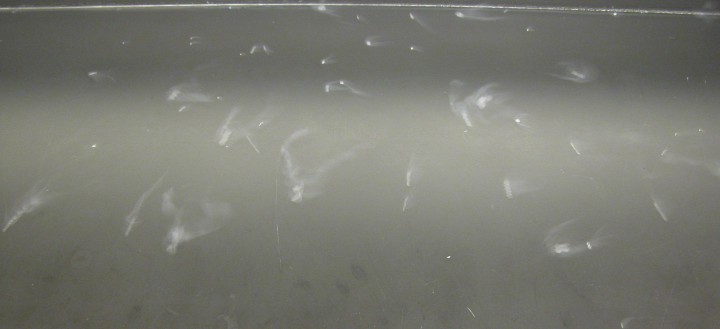

- BELOW: Droplets of liquid nitrogen exhibiting the Leidenfrost

effect.

-

-

- NOTE:

- Liquid nitrogen based geyser, base surge, and downburst demonstrations have been moved to Demonstrations Page 9 - Geology.

-

- Soap Suds Explosion

- I saw this demonstration on the "David Letterman Show"

and just had to try it. It simply involves quickly pouring liquid

nitrogen (WARNING: Extremely COLD!) into hot water (WARNING:

HOT!) containing dishsoap. The liquid nitrogen flashes to nitrogen

gas, causing a large explosion of rather cool soap suds. This

demonstration is best done outside since so many suds are produced.

An awesome demonstration of phase changes!

-

- BELOW LEFT: The soap suds explosion.

- BELOW RIGHT: Aftermath of the soap suds exposion. I got suds

all over me from this one (note the suds on the step rails and

on the ground).

-

-

Return to Dr. Campbell's Favorite

Demonstrations

Last updated 1/17/12

Site created at the laboratory of Dean Campbell

>>>

bend >>>

>>>

bend >>> >>> apply heat >>>

>>> apply heat >>>

>>>

bend >>>

>>>

bend >>> >>> apply heat >>>

>>> apply heat >>>